Our Equipment

Advanced Manufacturing Infrastructure

To deliver world-class aluminium alloy products, we rely on modern, efficient, and highly precise equipment. Our production line is equipped with the latest technology, enabling us to produce alloys that meet both standard and custom requirements.

Our Key Equipment Includes:

- Rotary Furnace of Monometer England, BoƩom casting stationary type 2.5 MT molten metal Capacity with 4 times rotation of production of 10MT per day.

- Reverobatory Furnace 5MT metal capacity with 3 times of 15MT per day rotation of production.

- Holding Furnace with Crucible Hydraulic Tilting type, 250 Kg of Aluminum molten metal capacity.

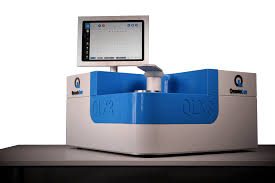

- Advanced CCD Based Optical Emission Spectrometer “Q4 Tasman” Bruker Quantron GmbH.

- Optical Emission Spectrometer “Baird” & “SpectroLab” for analyzing of metal Alloys.

- Smoke and Air Pollution Control unit with Water Scrubber.

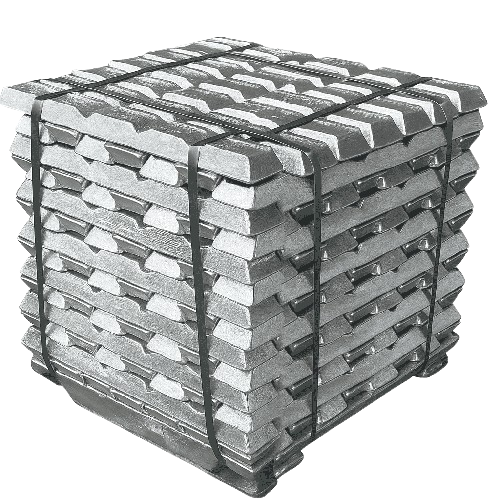

- Ingot Casting Conveyor with 160 moulds capacity.

- Bailing Machines

For accurate post-processing and surface finishing of alloy components.

Our investment in high-end equipment ensures that we maintain production efficiency, meet

demanding tolerances, and consistently deliver top-quality products.

Induction Melting Furnaces

Advanced induction melting technology for precise temperature control.

Vacuum Arc Remelting Systems

For production of high-purity, defect-free specialty alloys.

CNC Machining Centers

Precision machining capabilities for complex components.